PET preform mould, preform mould maker in China

For over 10 years, TopWorks has been the go-to source for reliable, affordable PET preform moulds. Our experienced team uses modern technology combined with the highest quality materials to create molds that are durable and cost-effective.We have earned the trust of both local and international customers, thanks to our commitment to customer satisfaction. Our staff is continuously refining and innovating the production process to ensure the best quality results.

Our confidence in the quality of our PET preform moulds is backed by more than a decade of experience, and we guarantee that our products will meet the needs of our customers. If you’re searching for quality preform molds at competitive prices, TopWorks is the perfect partner.

Our company has gained extensive skill and expertise in preform mould, allowing clients to trust that they will receive top-class service, efficiency, and commitment.With the capacity to build a full set of PET preform moulds promptly, accurately and cost-effectively no matter how elaborate, Topworks is ready to meet any customer needs.

Beyond this, we are also able to design and make each PET preform to customers’ particular specifications, as well as provide printing options on each one.

“I’m glad to inform you that all plastic parts are perfect!!! We are delighted, and therefore there are good chances to continue our relationship for any coming new project.”

CRISTIANO

ITALY

“Steven is a very detail-oriented project manager and engineer who can solve problems creatively and also provides excellent service. It was a pleasure working with him.”

DAVID

USA

Overview of company’s PET preform mould making

PET Preform Mold Design

- Technical design considerations

- Mold configuration (cavities, layout)

- Gate design

- Cooling system

- Ejection system

- Venting

- Surface finish

- Tolerances

PET Preform Mold Materials

- Tool steel options

- P20

- H13

- 420 stainless steel

- Other alloys

PET Preform Mold Making Process

- Steps involved

- Mold design

- CNC machining

- Heat treatment

- Finishing

- Assembly

- Testing and approval

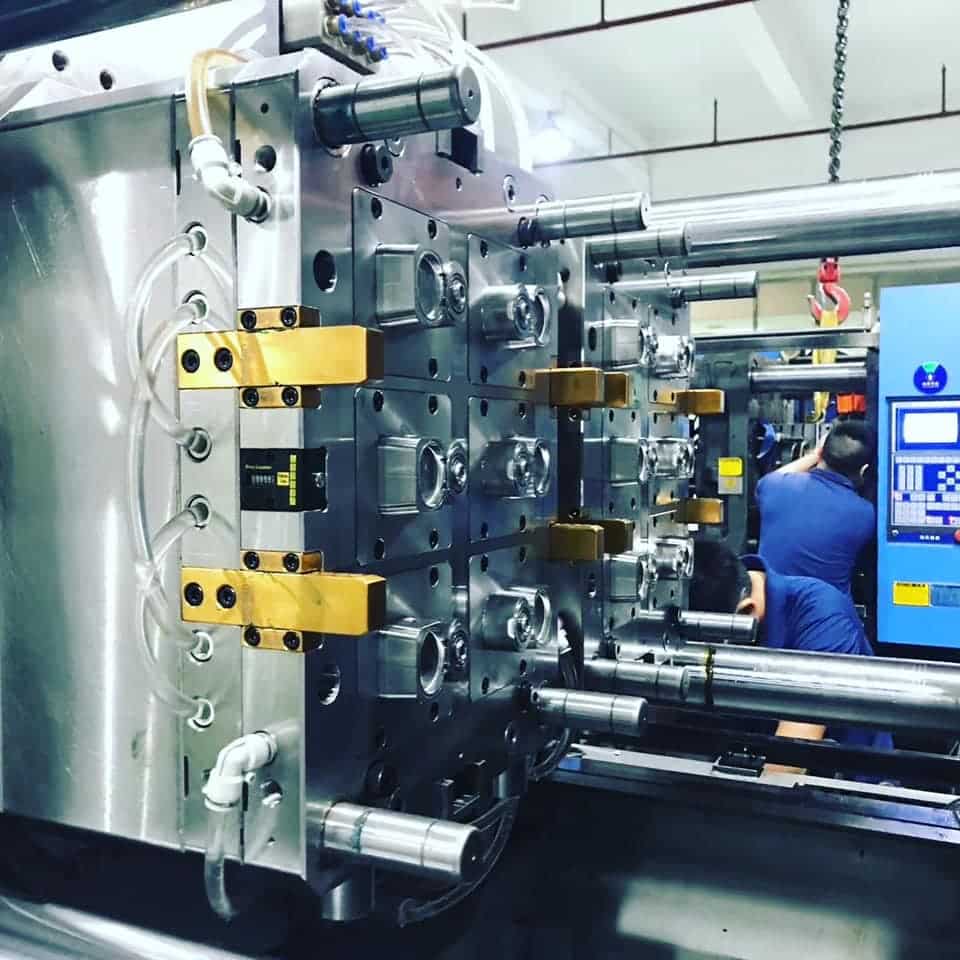

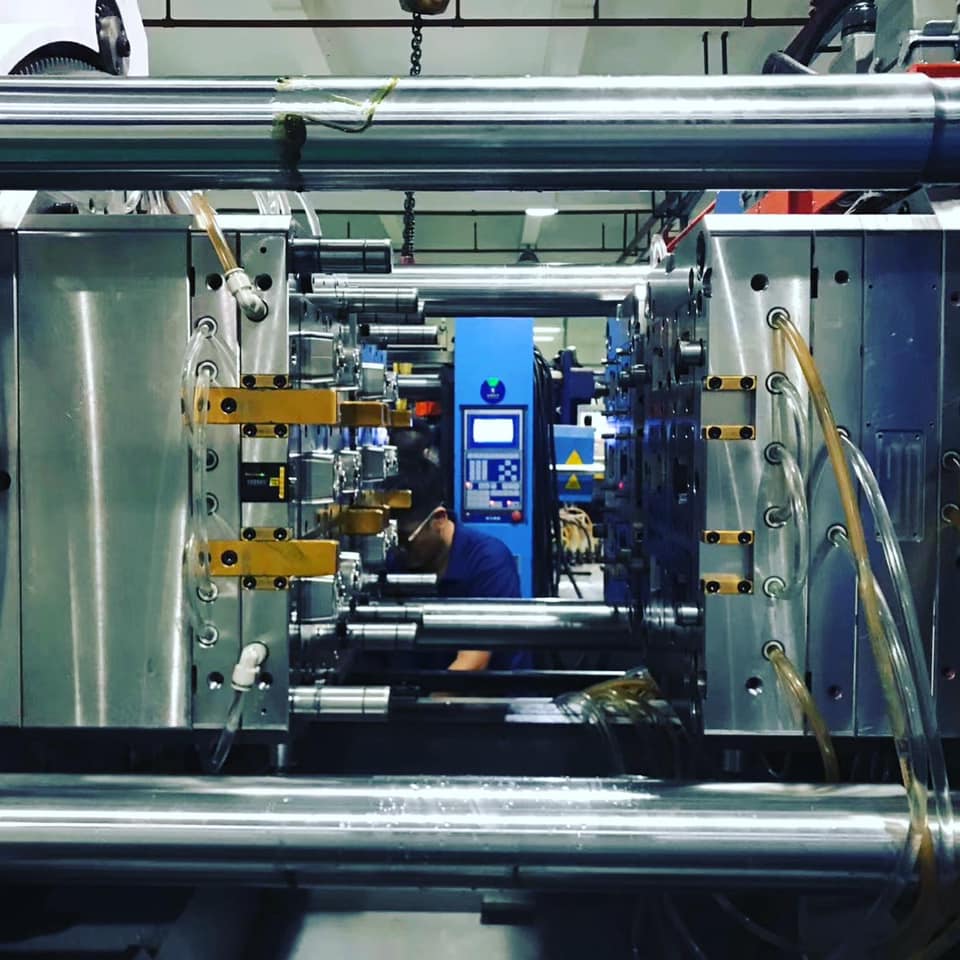

Our team

Topworks’ experienced and committed workforce specialize in multiple divisions to provide designing and building of moulds for creating unique features tailored to different kinds of PET plastic preforms. We have a full range of plastic preform mould manufacturing capabilities and create molds in a pleasant working environment.

Our preforms are available in our facility and can be made in-house or customized to your packaging needs with an individual preform mould crafted from PET. This service allows you to make everything you need in one convenient location.

How to use PET preform mould?

Polyethylene terephthalate (PET) is a naturally occurring thermoplastic polymer commonly used in plastic products. As of today, GF-PET is the most popular polymer among customers, which is mainly used in preform injection.

Consequently, the properties of PET in a liquid state are much better, and pressure is more important than temperature in terms of viscosity. In this situation, the fluidity of the melt is often affected mainly by pressure.

Plastic Processing

Due to its lipid-related nature and its hydrophilicity, PET pellets are very sensitive to water at high temperatures. Also, due to their presence, PET has a phospholipid-based structure. PET loses molecular weight when moisture levels exceed the limit; the product turns color and becomes brittle.

It requires drying at 150 °C for at least four hours, generally 170 °C, over three to four hours, before processing. Recyclable materials should be no higher than 25%, and they should be thoroughly dried before use.

Injection Molding Machine

Injection systems with temperature control sections and low friction heat are required since PET has a stable time after melting and high melting point, and the actual weight of the plastic should be 2/3 of the one-shot amount of machine injection.

Mold and Gate Design

Hot runner molds are used to manufacture PET preforms. A heat insulator is sometimes placed between the hot runner mold and the injection molding machine. Preforms are about 12 mm thick, while insulators have to withstand high pressure.

The venting slot depth must not exceed 0.03mm; otherwise, the flash will easily occur.

Melting Temperature

The optimum temperature range can be set between 270 and 295 ° C using a shot-to-air method.

Enhance grade GF-PET can be set at 290-315 ° C.

Injection Speed

An injection speed of 2 to 4 seconds is usually adequate to prevent early coagulation in the material. But too fast can make it brittle. The shot takes four seconds.

Back Pressure

It’s best to inject at low pressure, no more than 100bar, so the injection doesn’t wear off.

Residence times

Keep temperatures below 300 °C and avoid residence times over 15 minutes to prevent molecular degradation. The barrel should only be air-blasted for 15 minutes; if more time is needed, clean it with viscosity PE and turn the barrel temperature down to PE temperature.

Others

It is important not to use too much recycled material in case it will negatively influence plasticization.

It is possible to produce “white fog” and opaque if the mold temperature is not well controlled.

| mold life | <0.2 million | 0.2-0.5 million | 0.5-1 million | > 1 million |

|---|---|---|---|---|

| insert steel | P20/PX5 738 | NAK80/718H | SKD61/TDAC(DH2F) | AIASA420/S136 |

| insert hardness | (30±2)HRC | (38±2)HRC | (52±2)HRC | (60±2)HRC |

| base steel | S55C | S55C | S55C | S55C |

| base hardness | (18±2)HRC | (18±2)HRC | (18±2)HRC | (18±2)HRC |

Why valave hotrunner system for PET preform mould

The initial price and delivery are often driving factors in today’s injection molded preform. As a result of this sort of PET mold acquisition, molded parts will not be at their long-term economic advantage for companies producing the first generation of parts. At the same time, even short-run molds will not contribute fairly to the bottom line profits. Tooling is often modified when molders make a new generation of the same basic part, believing that by doing so, the pPET preform production will be so successful that the competition will not win the contract. An opponent with long-term parts production molds, which have the best ROI compared to a production run, will be in a stronger position in rebidding, especially if the same procedures reflect the entire company’s outlook.

When selecting a system, consider these factors

Injection molded PET preform, whether short-run or long-run, need to be evaluated from the points below. All aspects of an economically successful PET preform mould operation must be considered when selecting a gating system: its cost, trial costs, setup times, cycle times, maintenance, scrap, secondary operations, auxiliary equipment, and the quality of its parts. Mold size is enhanced by the runner and offset of the cavity from the sprue bushing in a cold bushing, single cavity mold with edge-gating of the part. With well-designed systems, the resin will be moved to the offset with the minimum increase in PET preform mould size via a low-profile hot runner.

Hot runner costs are offset by reduced PET preform mould size

Even if the PET preform mould size is reduced, the hot runner’s initial cost may be offset, allowing the press size to be chosen based on part requirements. The valve gate to the parting line reduces the amount of resin required per shot, thus reducing scrap (sprues) and regrind volume required. It makes economic sense to use a hot runner to replace mold offset for all parts over 50g with an expected life of more than 150,000 pieces. Due to the expensive mold base for a cold runner system, the number of parts may be lower when the part is larger, but the cost of hot runners will stay the same.

PET preform mould sprue bushing advantages

Molds that gate directly into a single cavity using a sprue bushing have several advantages over cold runners. Based only on the part requirements, the PET mould base size will be determined by the smallest press. By using cold sprue bushings, sprues are created, which must be removed, leaving marks that frequently need to be removed through secondary operations if appearance or maximum height of the sprue remnant are concerns. Hot sprue bushings are commonly used to prevent this, but often leave an unacceptable mark, reduce the operating window, and create internal part stress (warpage).

By using a valve gate system, an unacceptable mark will not form, a good operating window is maintained, and the PET preform is provided with the least amount of stress. Valve gate systems typically require a larger mold for their operating system, both in terms of mold footprint and height, because they must use a hot runner to offset the operating mechanism from the centerline of the mold, and have to fit a manifold and their operating mechanism in the mold. Most suitable systems will achieve this without increasing the footprint of the PET mold, and often without affecting the height of the mold, since the valve gate is situated on the centerline of the mold and does not require external operation.

Bigger PET preform mould as a Result of Cold Runner

The size of the preform mould is often increased when designing multicavity moulds with cold runner systems in order to fit the runner, slides, and mechanisms, which in turn makes it more difficult to orient the cavity during complex part design. If part modification or long process times are involved, the molding process operating window becomes very restricted and warpage is almost impossible to control.

In the manufacture of three-plate molds, cavitation levels are high, cavity layout is optimal, and automatic operation is possible. The incorporation of a hot runner system with direct thermal gating in place of traditional mold construction will allow the multicavity mold to be utilized in a more economical manner–smallest parting line surface per part, low mold height, shorter cycle times, least scrap, and best automated operation.

In addition to reducing cycle times, valve gated hot runners reduce part stress and produce better quality preform parts. In contrast, new valve gated hot runner systems, which increase mold height no matter what and are less expensive, can greatly reduce the costs and mold height increases of traditional valve gated hot runner systems that have a detrimental effect on economic efficiency. Hot runners may be ordered for the entire “A” half minus cavities in order to assure better mold delivery times. Mold construction time can be reduced by spreading the workload across more facilities.

PET preform mould Hot Runner System Offers Cost, Time, and Waste Reduction

A hot runner system has been applied to the acquisition of preform mould and has proven to be an efficient way of reducing the initial cost, construction time, and operational costs of trials, setup, cycle time, maintenance, scrap, and secondary operations-and without requiring any additional equipment. As a result, most applications will be able to expect a consistent level of quality. A hot runner thermal gated system or a valve gate system is frequently specified to produce a high-performance molding design. Using these types of machines, you will achieve very high shot-to-shot repeatability, faster cycle times, easy mold operation, and high-quality parts. Thermal as well as valve gate systems designed well will generally outperform those designed poorly. With such a system, less mold height and less power is needed, plus no external controls or auxiliary power systems are required.

Almost any PET preform mould acquisition should consider a hot runner system due to the advantages it will provide overall. To obtain the advantages necessary for competitive injection molded parts production in today’s market, valve gate installations should be performed as per the manufacturer’s specifications. Valve gate systems are superior to thermal gate systems because all components are constructed very simply and robustly, from a simple design concept of as few parts as possible to provide the best gate flow control.